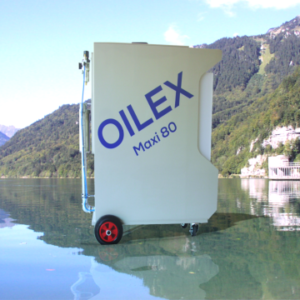

Oil separator OILEX Maxi 80

For the optimum care of cooling lubricants

and aqueous solutions

When operating machine tools, operating oil/grease of the machine always enters the emulsion. This creates bacteria and thus leads to skin irritation, unpleasant odors and smoke development in the workplace. The service life of the tools is deteriorated by the foreign oils in the coolant, since optimum cooling is not ensured.

Due to the reduced service life, the costs for disposal and procurement of new coolant concentrate increase.

The separation of the tramp oil from the coolant emulsion is based on the coalescence principle. The OILEX oil separator sucks the floating tramp oil from the surface in the coolant tank via a float. In the oil separator, the tramp oil rises to the top and is discharged into the collection tank. The small oil droplets are also brought together in a basket, which gives them the buoyancy they need to rise to the surface. The cleaned medium flows back into the coolant tank of the plant

Technical data:

Stationary unit (we do not recommend using the unit as a mobile unit to prevent bacteria from being transferred from one unit to another).

Compressed air drive

made of PP housing, stainless steel pre-filter with washable filter cartridge 250u, tramp oil tank 35 liters

Labirint filter

adjustable flow rate from 100 l/h to 800 l/h

Mass (L x W x H) 870x380x1200mm